-

Notifications

You must be signed in to change notification settings - Fork 7

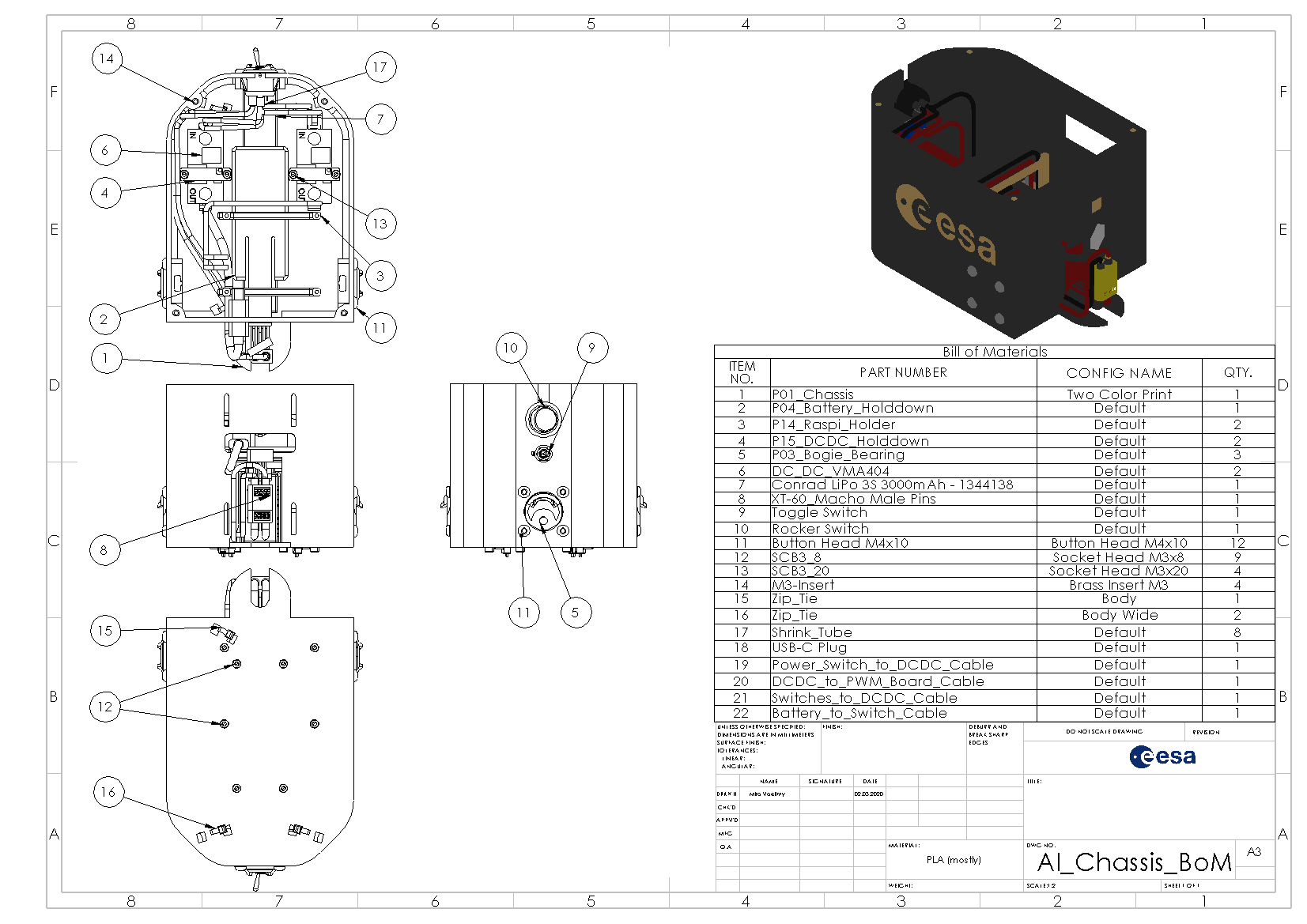

Chassis Assembly

The chassis should have the threaded inserts installed as described here.

Make sure the threaded inserts are installed in the chassis as described here.

Start by installing the bogie bogie bearings with the M4x10 bolts into the chassis. Make sure they are oriented with the hole positioned on the bottom.

A drill can make the installation process faster. Be careful however not to over-tighten the bolt as the thread can easily break; meaning the screw could rotate freely without holding the parts together.

Double check the orientation of the bogie bearings on all three. This would be very annoying to change later, the circular hole should be towards the bottom.

Look of chassis after installation of bogie bearings.

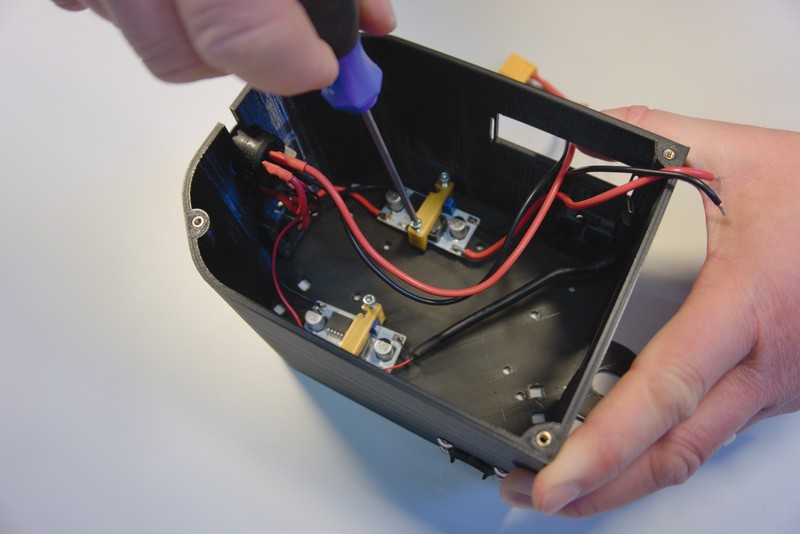

Now install the wire harness containing the switch, connectors and dc/dc convertors.

Start by inserting the power and motor switch into the chassis. Be aware of the notches that prevent the switch from rotating and install the switches according to their cutouts on the chassis.

Put the washer on first, so the teeth point towards the plastic, and use your spanner or pliers to tighten the motor switch nut.

View after installation of switches.

Next up is the installation of the DC/DC converters using the DC/DC hold down bracket and four M3x20 bolts shown bellow. Try not to press on the various components on the board as they can bend and break easily.

Ensure that the adjustment screw of the DC/DC converter is still accessable and located in the dedicated cutout.

Route the battery cable allong the right wall of the chassis and secure the DC/DC power cables with zip ties. The USB cable is left free and routed through the top of the battery cutout in the dedicated slot.

Give the zip tie a kink before inserting it from the bottom in the three designated cutouts.

Finally tighten and cut the zip ties.

View of chassis after installation of the wire harness.

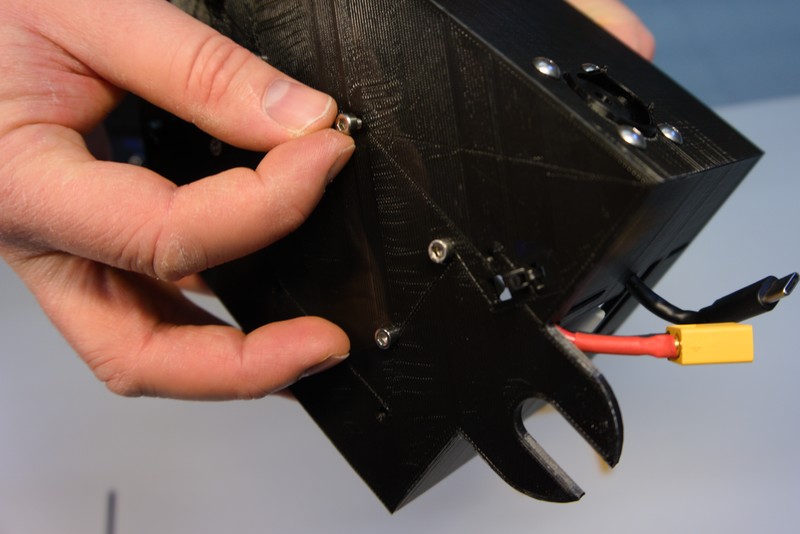

With the wire harness secured, it is time to install the battery. Depending on which battery is needed you might have to slightly alter the design of the battery hold down bracket.

Align the bracket with the chassis and start fastening the bracket with the M3x8 bolts. Here, the thread is cut directly into the plastic. Thus be careful not to overtighten and rip out the thread.

It is generally good practice to first install all screws loosly and only then tighten them one by one.

Now insert the battery from the front with the cables coming out on the bottom.

Next, install the brackets that will later hold our Raspberry Pi. The Raspberry Pi itself should not yet be installed however.

The proceedure is the same as for the battery hold down.

Ensure this time that the bracket is oriented correctly as depicted bellow. The upper screw holes should be closer to the port cutout on chassis.

Don't worry if they don't look straight at this stage, the Raspberry Pi mounting screw will align the brackets later.

The chassis assembly is done and the assembly continues with the assembly of the three bogies here.

Build

- Getting Started

- Purchasing Instructions

- Software Instructions

- Manufacturing Instructions

- Assembly Instructions

- Optional Parts

Use

Contribute

Help